Ah, let’s break this down. So why would it be a conflict of Interest to have an accredited EMI-EMC Test Lab and an EMI-EMC consulting service? I have grappled with this question until recently because I am an EMI/EMC Consultant. However, I also wanted to set up an accredited EMC test lab because I already know how to run these tests and have much of the same equipment these labs use.

Funny, how God will often bring people into our lives who intentionally or unintentionally show us the answers to the questions we struggle with. Hearing the story from a new prospective client who had lost their patience with repeated compliance test failures down in North Carolina, and his frustration on the wasted time and money he spent on the lab tech’s trying to provide a “quick-fix” so his unit would pass compliance made it so very clear of the dubious conflict that supposedly independent testing and “fixing” the problem posed.

This is when the product designer needs to call an external independent consultant, an EMI-EMC Consultant like ELEXANA, and this is why we are no longer going to strive towards converting our Pre-Compliance Test Lab or our Mobile EMI-EMC Test Lab into accredited test labs. Running pre-compliance tests to check if the design modifications we are working on will pass is way less expensive than going to an EMC Test House to do this, sometimes, a back-and-forth process.

EMI Pre-Compliance testing software will typically present the Compliance Standard’s Pass-Fail threshold lines and a dotted line 6 dBµV (decibels microvolts) below the threshold Pass-Fail line of demarcation. Pre-Compliance design aims to have all frequency amplitudes below the dotted line. This way, there is more confidence in not wasting more funds at an EMC Test House.

Usually, the EMI Consultant is hired for a certain number of days to work with you and your team at your location. The number of days is determined by the time the developers have already struggled, the complexity of the DUT (Device Under Test) or EUT (Equipment Under Test), and the number of failed test frequencies.

Here is a more detailed outline of why using an accredited compliance lab would be entering into a conflict of interest in identifying why a product cannot pass compliance and making efforts to remedy this problem.

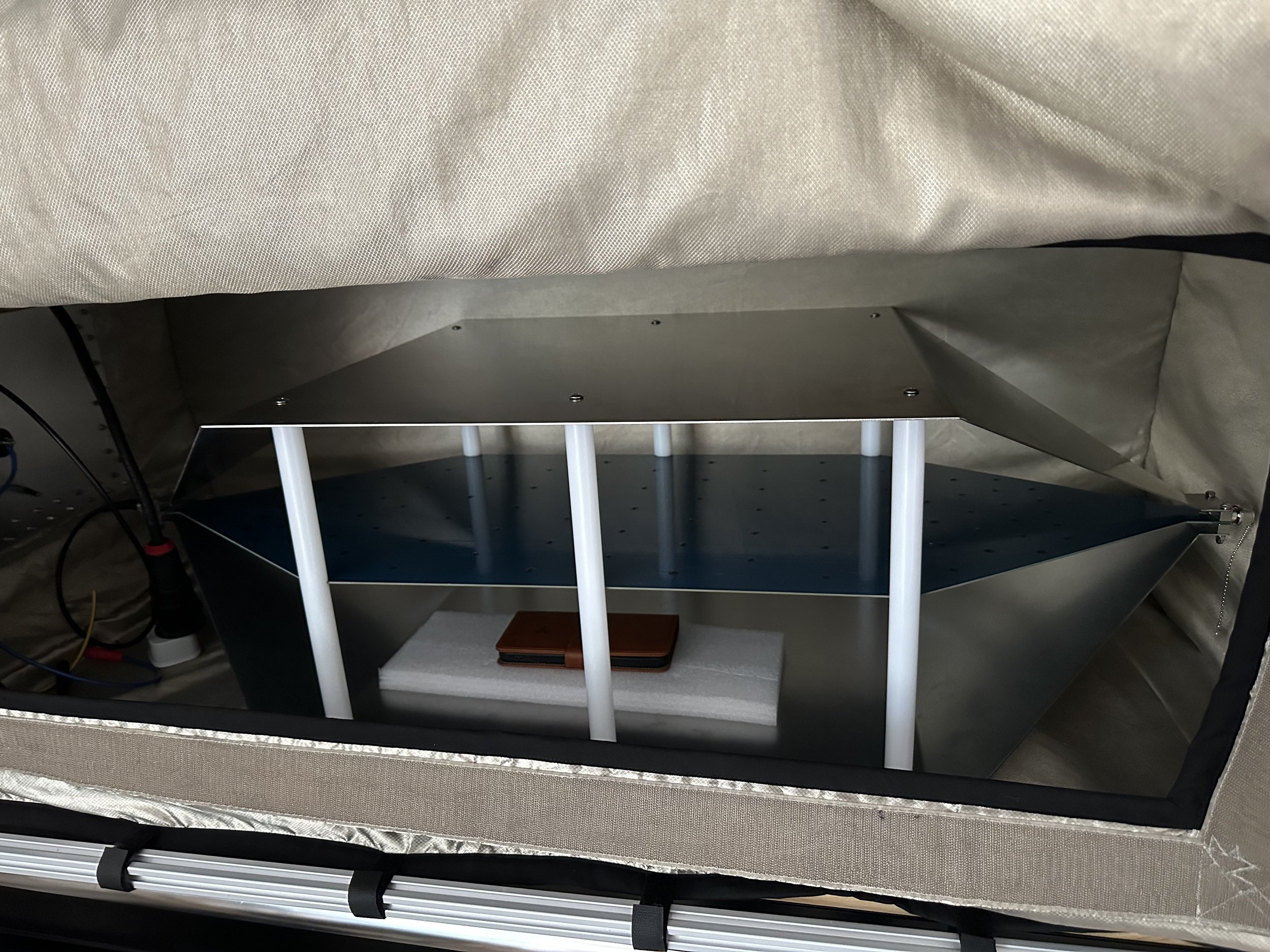

Here is one of our TEM-cells (Transverse Electromagnetic Cell), a test chamber, inside a Faraday Cage. You can see the DUT on the dielectric material. This TEM cell is connected to our EMI Receiver which contains the EMC Pre-Compliance software. This system for testing small products, PCBs, or power supplies, for radiated emissions is very accurate.

Why It Can Be a Conflict of Interest

1. Compliance labs are paid to test, not to fix

Accredited labs (e.g., for FCC, CE, MIL-STD) are typically certified to run standardized compliance tests and report pass/fail results.

Their role is verifying compliance, not independently advising or engineering product fixes.

If the same lab that certifies compliance also offers “for-hire” troubleshooting services, it creates an incentive to:

Prolong testing or problem identification to increase billable hours.

Blur the line between neutral assessment and commercial involvement in redesign.

2. Accreditation rules emphasize independence

Many standards bodies discourage or forbid accredited labs from acting as design consultants on the same product.

The lab’s value is in providing impartial verification — if they help solve the problem, they effectively become part of the design team, which can undermine the neutrality of the certification.

3. Potential for biased recommendations

A lab offering investigation services might advocate fixes or retesting that favor its process, tools, or interpretation rather than an optimal or independent engineering solution.

4. Liability and legal clarity

If a product fails compliance after passing through both the lab’s investigation and certification services, it raises difficult questions:

Was the lab objective in its assessment?

Did it miss or cover up issues to preserve the client relationship?

Who is liable for the failure?

How to Manage This:

Use separate teams or organizations:

Accredited labs should handle compliance testing only.

Independent EMC/EMI consultants should investigate, diagnose, and help fix the causes of failure.

Ensure clear contractual separation between testing and troubleshooting work.

Be cautious if a lab offers “help” beyond its accredited testing scope — ask about their independence and how they manage conflicts.

At ELEXANA we work for our clients, not for ourselves.

©2025 All Rights are Reserved.